Case Studies

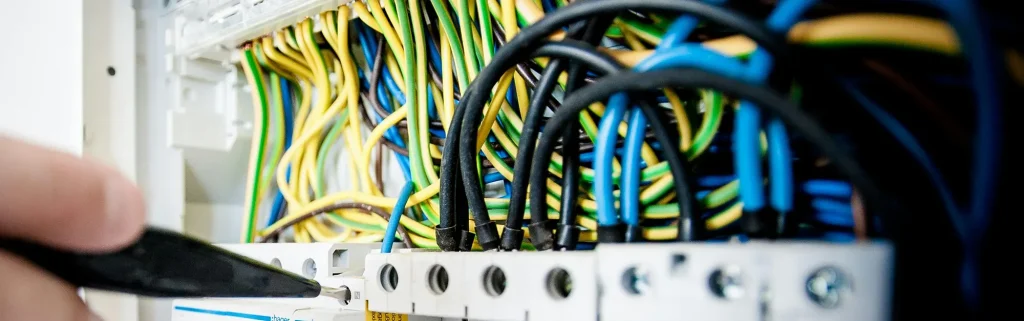

1. Enclosure Build

Machine Electrics worked with an automation provider to design and construct a large motor control centre (MCC) and several custom operator console panels. Each unit was built for reliability, clear operator interface, and future expandability.

2. Motor Soft Start – Wood chipper

Machine Electrics designed and built a soft start solution for a large wood chipper motor. The new setup provides smoother start-up, reduces mechanical stress, and enhances long-term equipment protection.

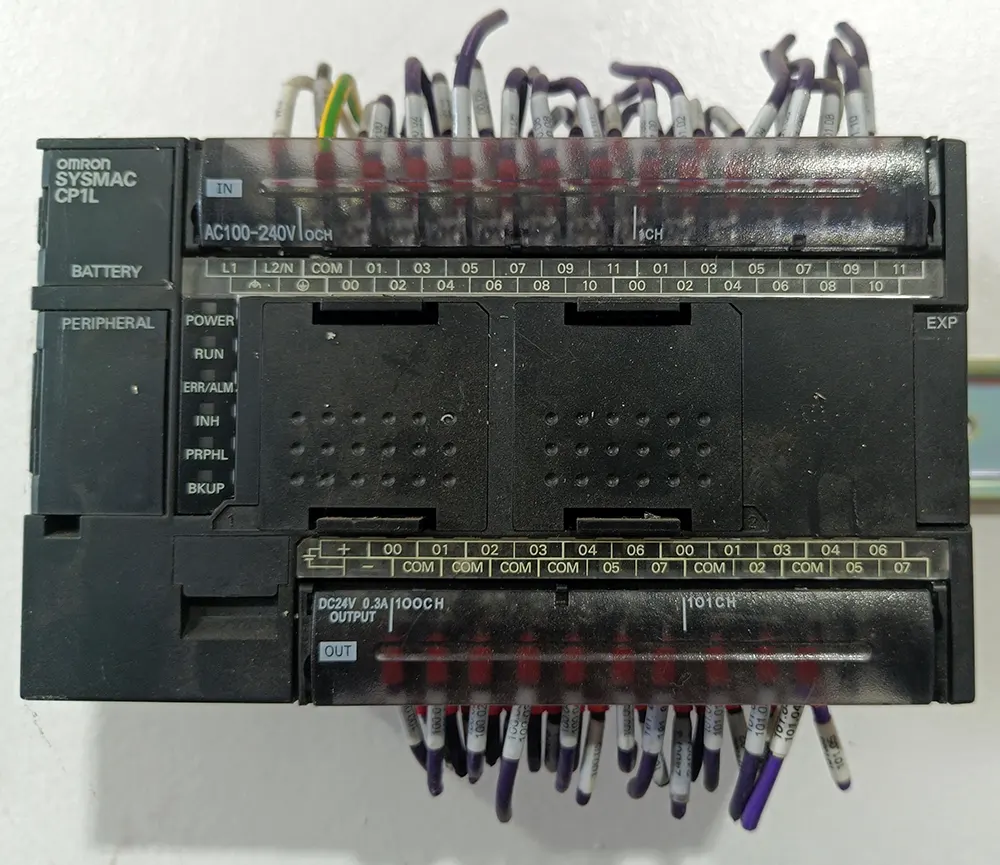

3. PLC Retrofit

A client’s machine control system was becoming obsolete, and replacement parts were no longer available. Because the machine was critical to operations, we upgraded the PLC and control system to a modern, reliable, and easy-to-use setup with full support availability. The new PLC interfaces seamlessly with the existing electrical field components, maintaining functionality while improving reliability and control. No need for downtime during the retrofit!

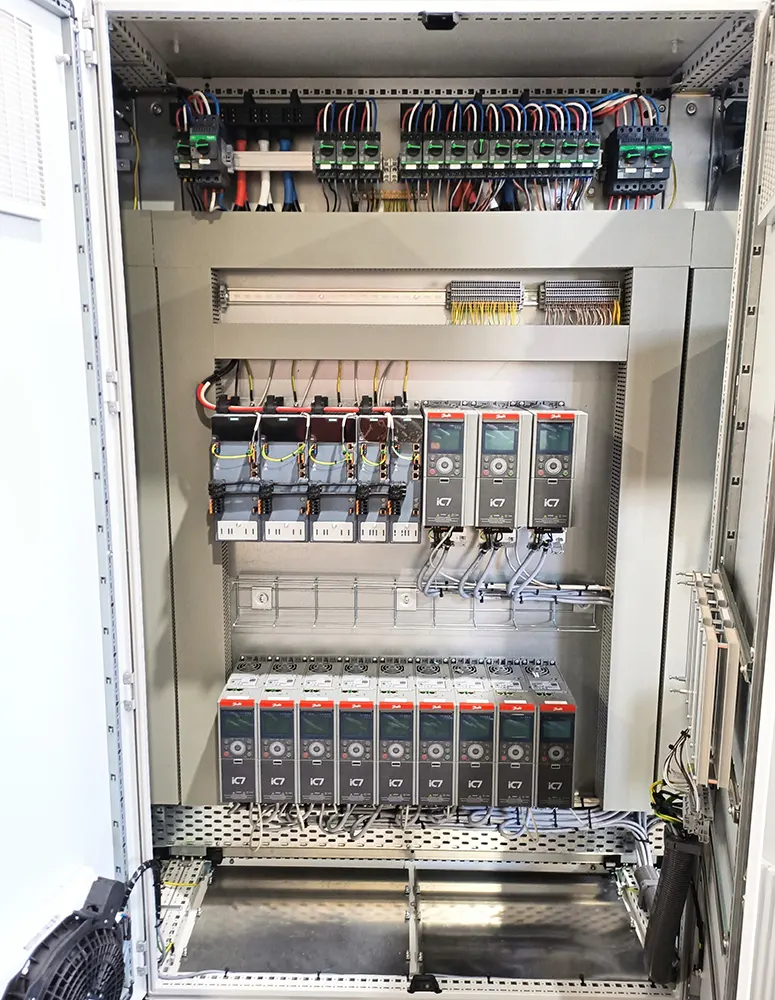

4. Machinery configuration change

Machine Electrics integrated a new automated conveyor system into an existing production line, reconfiguring the electrical enclosure to support additional hardware. We replaced older hydraulic equipment with modern electrical VSDs, allowing precise acceleration and deceleration while eliminating leaking hydraulic lines.

5. Electrical support and fault finding

Because we design and build our own machine electrical enclosures, we have a deep understanding of how systems work — which makes fault-finding fast and efficient. For example, when a wood planer’s safety system component failed, we quickly identified the cause and implemented a safe, permanent solution to restore full operation.